Hand Stain Tannery Tour

Posted by JOE FLOTO

Working with genuine hand stained vegetable tanned leather is a complete addiction. The supple skin has a sweet scent, is easy to cut and sand, strong and flexible, and does not contain any toxic or harmful substances.

We only source our hand stained leather from family tanneries in Tuscany that abide by tradition and strictly monitor the production to minimize the impact on the environment. The raw skins come from small meat and dairy farms in America and Europe that have high moisture content - this is because the hand stain process only works with supple leather. A drier, more brittle leather does not absorb the vegetable tannins as well and is not worth the artisan effort put into hand staining.

The tannery below produces our Vecchio Brown, Olive (Honey) Brown, Tuscan Red, Navy Blue, Green, and Black leathers. This 4th generation tannery has been rolling drums in the hills of Tuscany since the 50s.

The Beamhouse

The main stages of leather tanning occur over several days in large wooden drums where the raw salted skins are hydrated, cleaned, and then split in skivers to produce a naked leather hide that is ready for hand staining and painting.

The Blank Canvas

Before the hand stain process can begin the naked leather hides are put into a large drum tumbler that softens the skins so the vegetable tannins will absorb deep into the grain. The softened skins become the blank canvas.

The Stain Room

The stain room is where the blank canvas becomes a masterpiece. Vegetable tannins are mixed with secret ingredients to create non-toxic paint that is used to penetrate deep into the skins. Working in sections, the artisans carefully hand stain each skin using a special cotton sponge.

Using circular motions the artisans paint flower patterns into the grain - this is the fiore. A trained eye will look deep into the grain of a finished skin for the fiore - which is the artisanal stamp of authenticity.

The Drying Rack

The leather skins are hung to dry on a specially designed conveyor hanger - can you identify the Vecchio Brown, Olive Brown, or Tuscan Reds?

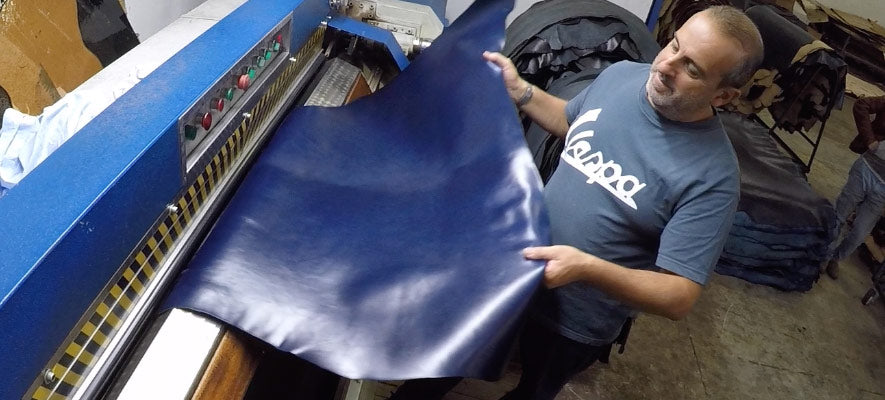

The Spray Machine

After a 48 - 72 hour drying period the hand stained skins are put through the spray machine for additional coloring. The spray machine runs the length of the tannery - half of which is a dryer.

At the end of the sprayer machine the leather skins exit the dryer section and are carefully stacked for more finishing.

Leather Stacking

The leather stacker is a machine that softens and fluffs the skin by rapidly shaking the leather. This prepares the leather for the final ironing stage.

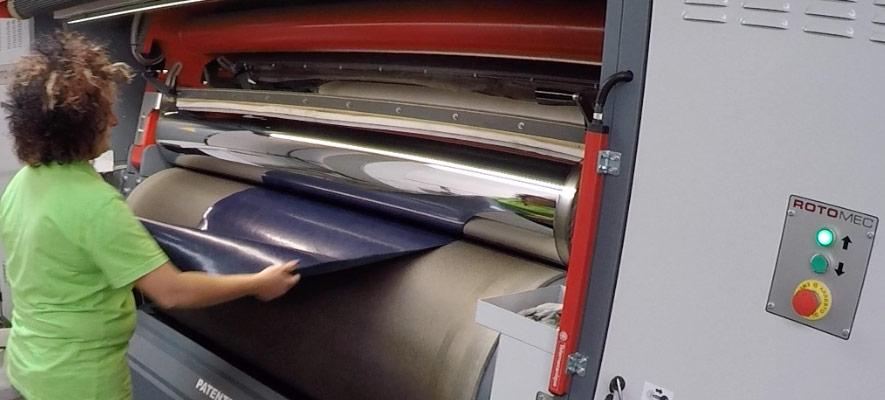

Matte or Semi-Gloss?

In life you can buy a Ferrari, or a massive industrial iron roller. These guys went for the roller and that's why we use them. This roller irons the leather to give it gloss. The more heat that you apply, the glossier the leather. For instance, our matte finish Roma and Saddle Brown leather is ironed at a lower temperature compared to our semi-gloss colors like Vecchio Brown or Navy Blue.